Engine failure is one of those problems that can feel like a write-off — but it doesn’t have to be. As engine rebuild specialists in South Wales, we regularly help customers avoid unnecessary replacement costs. Repairing or replacing an engine can be expensive, especially when the only alternative seems to be a brand‑new crate engine.

In many cases, a professionally reconditioned engine can save you 30–70% compared to buying new (depending on the engine and the level of damage). We focus on doing the job properly: careful measurement, quality parts, and a build process you can trust.

If you’re unsure which route is right, just get in touch with your vehicle details and the fault symptoms. We’ll help you choose the most cost‑effective and reliable option.

We offer three clear service levels so you can choose the right balance of cost, turnaround time, and originality for your vehicle. We’ll always advise which option makes the most sense before any work starts.

Fastest turnaround · Most cost‑effective

A fully reconditioned engine supplied in exchange for your existing unit (subject to availability). Ideal when downtime needs to be kept to a minimum.

Retain your engine number · Balanced turnaround

Your engine is rebuilt by us from the ground up using the same reconditioning process. This option is popular for higher‑value vehicles where originality matters.

Maximum convenience · Minimal refit time

Available alongside Tier 1 or Tier 2, this service delivers an engine ready to drop straight back in.

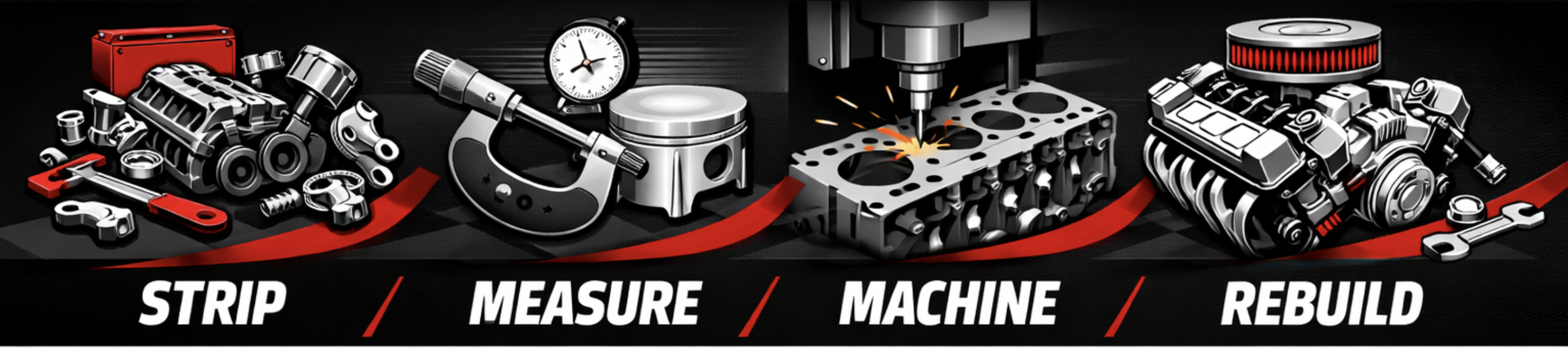

Every engine rebuild follows a careful, measured workflow. We strip, inspect, machine, and rebuild using quality parts — with reliability as the goal. (Exact steps vary slightly by engine type and the cause of failure.)

Engine is fully dismantled and components are chemically cleaned for accurate inspection.

Key parts are measured for wear and damage, including crankshaft journals, bores and cam surfaces.

Crankshaft is reground and polished as required, then matched with new bearings to suit.

Bores are machined as needed — either oversize (+0.50) with new pistons, or new rings with appropriate bore preparation.

Where the block requires it, we can supply and fit cylinder liners.

New oil pump supplied and fitted to support correct oil pressure and longevity.

All new gaskets and seals are fitted throughout the build, including a new head gasket.

Head is stripped; valves replaced or re-cut; new valve stem seals fitted; then skimmed and pressure tested.

New hydraulic lifters fitted. Camshafts checked and replaced if required. Timing chains/belts replaced using OE parts where applicable.

Not sure which service tier you need? Send your registration, mileage, and symptoms — we’ll advise the best route.

Commissions welcome. Drop us a line and let's talk on 0############

Email: info@theengineman.co.uk